(estimated reading time: 4-6 minutes)

For about 15 years, I’ve been making pottery full-time. First as a student, then by starting Cherrico Pottery. After handcrafting about 30,000 pieces of pottery, I can tell you from first hand experience that making pottery is really hard.

I’m a “production potter” which means I make pottery in repetition, in a variety of styles and colors, for people to eat and drink from. Each month, I handcraft about 500 pieces of pottery. Then, a team of employees sand, polish, pack and ship each pot to customers, for people to use and enjoy in their own homes.

It’s a good living, but that’s a lot of pottery to make by hand.

Repetitive work is tough. If you’re not careful, you can get overuse injuries:

-

- back strain from lifting heavy clay boxes

- neck and shoulder knots from hunched over work

- carpel tunnel wrist pain from throwing or sanding pots

For long-term sustainability, of both employees and me, I need to continually explore ways to reduce the strain on our bodies.

Two years ago, I began a research project. I tested having a version of my “Cosmic Mug” designed and made in a factory, by other workers. I created “Cosmic Mugs” to inspire us to think about how all human beings are connected, through the cosmos. So, why not use factories globally to create thousands, perhaps millions of mugs?

The goal was to get the price down to $19.95 for a pair, with free shipping, so anyone could afford Cherrico Pottery.

At first, China seemed like the perfect place to mass produce porcelain, a.k.a. “Fine China” because the Chinese have spent 2,000 years mastering the craft. With 1.4 billion people and hundreds of porcelain factories, they can make thousands of artistic mugs fast, cheap and with remarkably high quality.

After choosing a factory, I designed and bought roughly 1,000 mugs at about $10-$15 each. Most sold for about $26-$36 each.

That’s a pretty good start, considering over 800 sold and only 200 remain.

Next, I got a quote for a larger order of 10,000 mugs. They could be finished in 30 days, at around $4 per mug.

Sounds great, right!? That’s a 60%+ lower cost up front for me. That also means lower prices for customers– win win?!

Not exactly. I decided not to buy 10,000 mugs. Instead, I’m ending the project.

Why I’m Ending Our “Factory Designed Cosmic Mug” Project

After the remaining 200 Factory Designed Cosmic Mugs sell out, they’ll be gone for good. Seriously. No April fools.

Years of diving deep into the business of factory sourcing has given me one key takeaway: factory work is really hard on people.

I want my art to be good for all humanity, not just profitable.

For a quick glimpse of what it’s like to work in factories, these two documentaries are enlightening. Both helped influence my decision to start, and also end, my project.

American Factory

Manufactured Landscapes

Here at Cherrico Pottery, we considered building a factory ourselves, to have more control over how people are treated as employees. We already have a large studio. Maybe we should keep expanding.

Where would you rather work: a factory or a studio?

Factories make things faster, cheaper and more profitable. The problem is people are treated like machines.

Studios make things with creativity and connection. The problem is the products can’t scale in quantity, requiring higher costs.

The world needs both. But where would you rather work?

I’d rather work in a studio, but I’m also lucky enough to be able to say that, and choose that. Most people don’t get to make that choice.

For millions of people, perhaps billions, factory jobs are the only jobs available. Some factories might be wonderful places to work. Others might have terrible working conditions.

Regardless, if people didn’t need to work 8-12 hour shifts on the factory floor, do you think they still would?

Robots and Universal Basic Income

The world needs manufacturing. Most of the objects we’re surrounded by were made in factories, including whatever smartphone, computer or device you’re reading this on.

What will happen as robots continue replacing people in repetitive factory work? Robotic hands might even be dexterous enough to craft pottery soon.

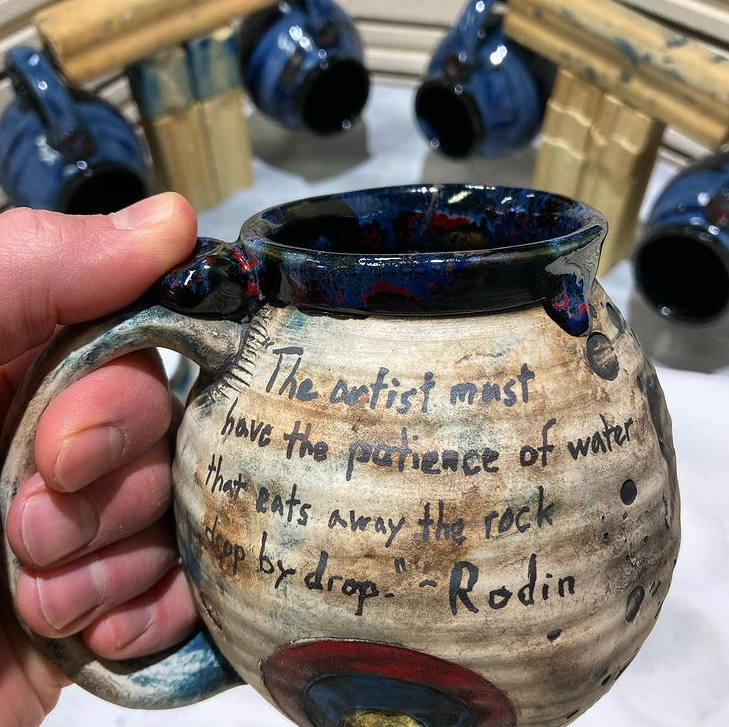

View this post on Instagram

Maybe robot help won’t be such a bad thing. Ideas like Universal Basic Income or “monthly citizen income” could let more people meet their basic costs of living. Then, perhaps more people could work on jobs that fulfill them personally. If machines can help reduce hard labor, why not let them?

After robots help reduce the hard, human cost of manufacturing, then maybe we’ll revisit using factories to make “Cosmic Mugs” affordable enough for anyone on the planet to experience them.

Until then, I’m headed back to the studio. No more time spent sourcing from factories. Instead, I’m putting that energy into exploring new art. The challenge now is making the best art I can, in appropriate quantities and fair prices, and trusting that people will still support it.