I remember the first time glazing a pot in Sam Johnson’s ceramics class last year. I had made this slightly uneven coil vase with pockmarked walls nearly an inch thick. The piece was truly ugly, an ogre really, but I couldn’t see the pot as anything other than beautiful. It was my Princess Fiona and I was its Shrek…At least until I glazed it.

Like most naive ceramics students, I pictured glazing just like painting. I picked out a handful of colors using the test tiles as my guide, and then brushed swooping glaze patterns all over my vase. By the time I finished, the pot looked like something straight out a kindergarten arts and crafts class. I on the other hand thought it was a masterpiece – a trophy of abstract art. When the thing (it was beyond a pot at this point) finally came out of the kiln, it was hideous. I looked over at my professor for encouragement. Sam walked over, took one look at my monster, turned to the class and said:

“Opening a kiln can be like Christmas or Halloween. Either the pots look amazing and you fall in love, or the results are horrible and you want to smash everything.”

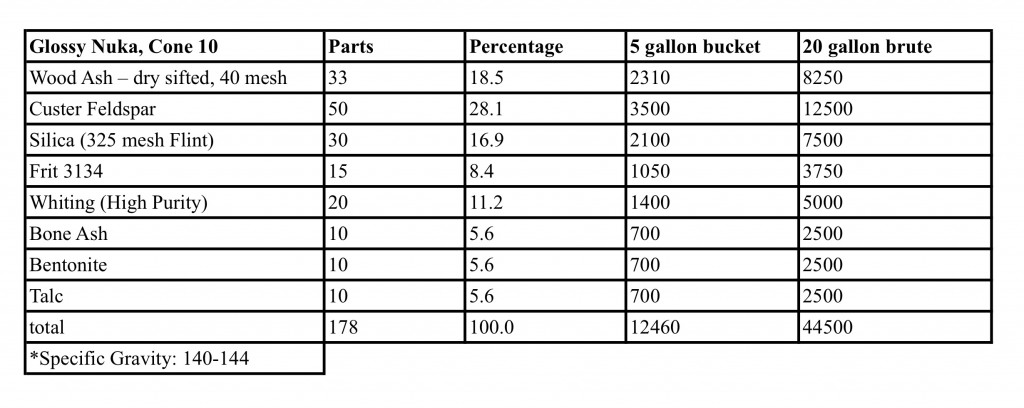

Unlike my great clay ogre, Joel can’t afford to make ugly pots. He makes his living through pottery, and as a result, his experiments with glaze need to be calculated and precise. He needs to know exactly how each part of the glaze works; how copper, cobalt, and iron make red, blue, and rust colors when the glaze reacts with fire in the kiln. Glazes transform clay bodies from ogres into princesses. However, as Joel continues to explore glaze chemistry, he finds that these potions are often difficult to create. Like the alchemists I wrote about last post, Joel works tirelessly to find the right balance of form and color that’ll turn a clay body into a beautiful work of art. For his livelihood, each glaze must reach for a certain standard of beauty.

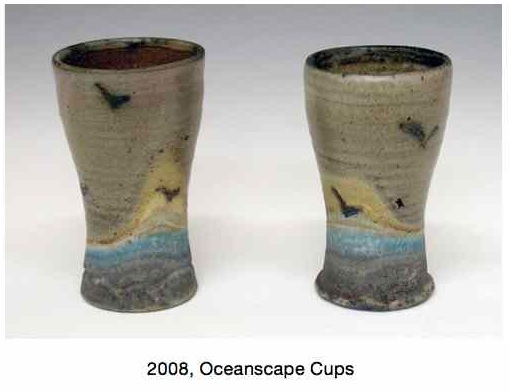

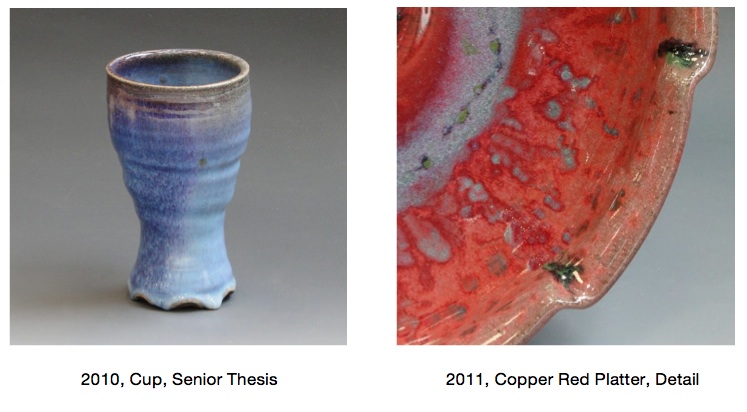

Looking back at his previous body of work, I think Joel’s been chasing this certain type of beauty all along. It’s been hidden in his work throughout the years, and now I feel we’re just starting to uncover it in the color blue.

Take a look at the gallery below to see an evolution of this blue color. Even in woodfiring, salt firing and copper red glazes, the color blue shows up. I can track the color throughout his work back to 2008:

Numerous potters talk about the lore of blue pottery. Throughout the ages, potters can’t seem to shy away from it. I’ve heard some contemporary potters even refer to the color as cash-flow blue.

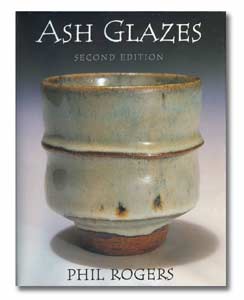

Our text book this semester has been Bernard Leach’s A Potter’s Book. Now a 50 year old text, Leach provides a rich history of how ceramics has evolved. His book not only offers rich lessons of the past, but it also gives insights into the future. But even Leach, who wrote the book after decades of experience under his belt, could not seem to understand the lure of the color blue in ceramics. These stories share his experiences with blue glazes:

“At my St. Ives workshop each summer we are asked by three visitors out of four for colour and yet more colour, blue and the more intense the better, is easily the favourite.”

– A Potter’s Book, page 36

“Yesterday we had a good bunch of people, 2 of whom at least knew a good pot when they saw it. One woman started by asking if we hadn’t got any ‘blue pots’, and when David showed them that the last olive-blue glaze for which we have experimented for years, she said: ‘Oh! Do you call that blue?'”

– A Potter’s Book, page 227-228

Perhaps what this all boils down to is something we talked about in the beginning -the pursuit of beauty. Some of the best potters in the contemporary art world don’t make beautiful work. Their work is strange, ugly and confusing.

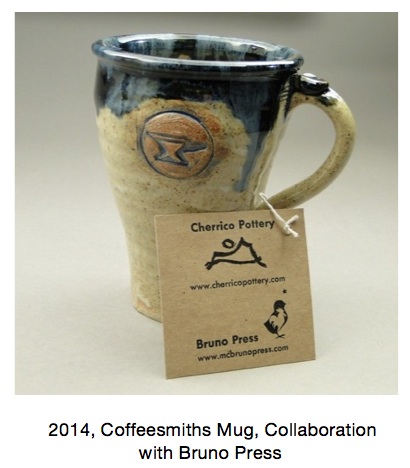

With this in mind, does the color blue still have a place in the contemporary ceramic world? This poster sits above our workspace, and it’s made from postcards Joel picked up in Philadelphia in 2010 at NCECA (National Council for Education for the Ceramic Arts). It gives a snapshot of the contemporary ceramic work, and shows only a handful of simple, blue pots. Joel will be at the conference in Milwaukee next week networking with contemporary potters and pottery enthusiasts. His goal is to show that the color blue continues to have a strong lure in both historical pottery as well as contemporary ceramics. He wants his work to be a bridge between historical potters like Leach and contemporary artists like Paige Dansinger. As a result, we’ve prepared some innovative market ideas, re-designed the website home page, and packed the online store with blue pots and artist collaborations with Dansinger. We’re prepared for the biggest ceramics conference in the country and we’re hoping to lure people to us with our blue pots!

With this in mind, does the color blue still have a place in the contemporary ceramic world? This poster sits above our workspace, and it’s made from postcards Joel picked up in Philadelphia in 2010 at NCECA (National Council for Education for the Ceramic Arts). It gives a snapshot of the contemporary ceramic work, and shows only a handful of simple, blue pots. Joel will be at the conference in Milwaukee next week networking with contemporary potters and pottery enthusiasts. His goal is to show that the color blue continues to have a strong lure in both historical pottery as well as contemporary ceramics. He wants his work to be a bridge between historical potters like Leach and contemporary artists like Paige Dansinger. As a result, we’ve prepared some innovative market ideas, re-designed the website home page, and packed the online store with blue pots and artist collaborations with Dansinger. We’re prepared for the biggest ceramics conference in the country and we’re hoping to lure people to us with our blue pots!